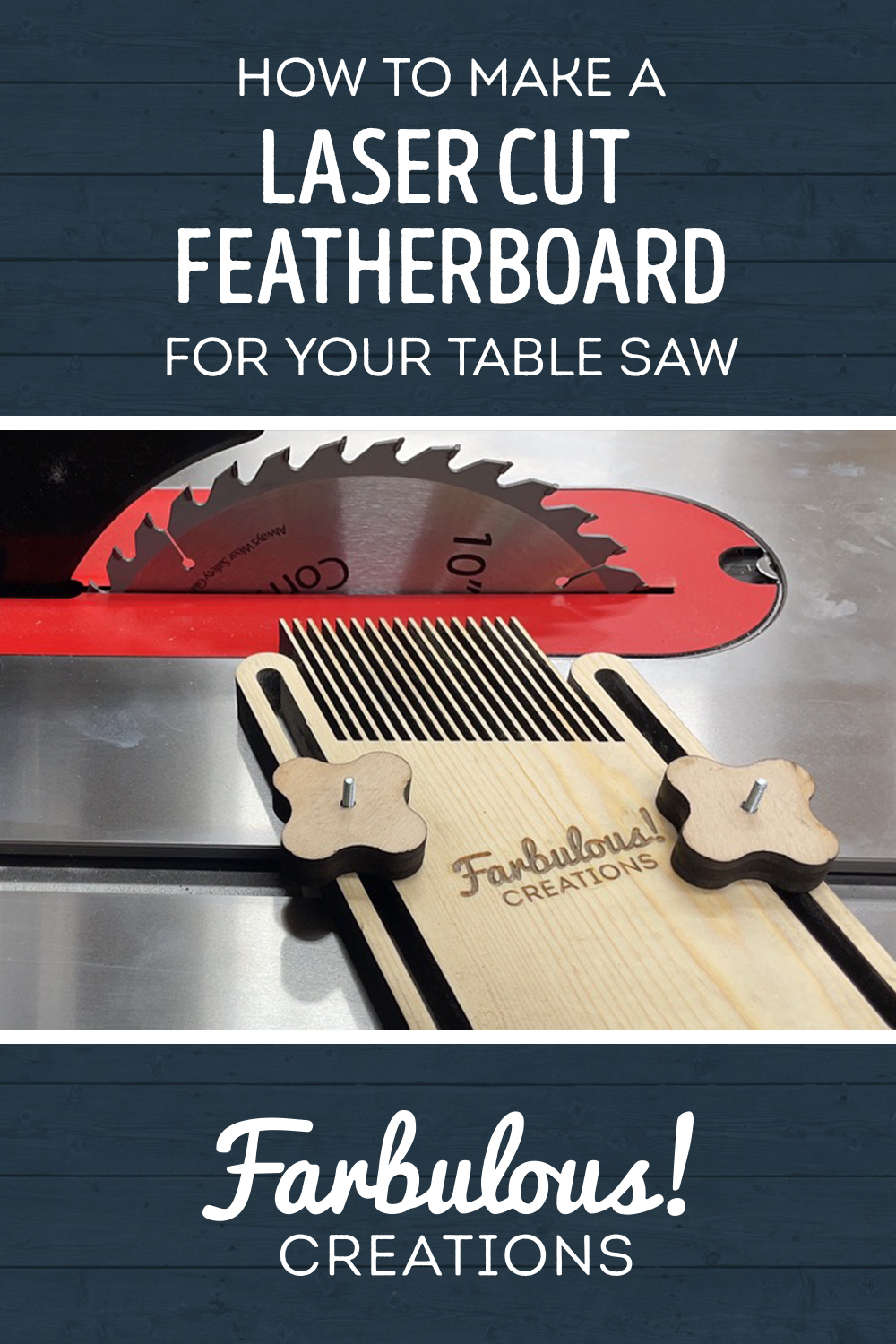

Welcome back to Farbulous Creations! I’m Ron, and today we’re going to use the laser cutter to create this featherboard for my new table saw. Let’s jump on in!

This is going to be the first in what is hopefully a series of videos I make about laser-cut shop jigs, tools and accessories. I’m an avid Redditor and subscribe to a sub called /r/FunctionalPrint and I absolutely love the idea of using the tools that we normally use to make creative projects to make more functional projects as well – that in-turn making creating creative projects easier.

Oh and for the uninitiated, a featherboard is a tool used to hold a board tight up against the fence of either a table saw or router table when it’s too dangerous or out of reach to do that action with a push stick.

The first step with any laser project, creative or not, is coming up with your cut files. I decided not to reinvent the wheel much here, as many a YouTube woodworker have already designed various DIY featherboards in the past. One of my favorites, and the one I’m effectively ripping off here, is by Steve Ramsey from Woodworking for Mere Mortals. He has plans for this featherboard available for free on his website, but it’s designed to be built with standard woodworking tools – a drill, table saw, jigsaw and a few others. As such, his plan document comes in the form of a raster image file, and not vector format. If it was vector, I might have been inclined to just cut it out with the laser and not make a video about it, as there wouldn’t be much else to say.

But since it wasn’t a vector file, and that’s what you need to do an outlined cut on the laser, I decided to use the measurements annotated in his plan to recreate it. I’ll be using Adobe Illustrator, my design tool of choice to create the featherboard’s outlines and vector paths.

One of my favorite parts of building or recreating something like this in Illustrator or other design tools is how powerful booleans, or as Illustrator calls them – pathfinder operations – can be to design something complex like this. Sure, you could in theory use the pen tool to literally trace the whole shape, point by point, but that would take a lot of concentration, a ton of clicks, and it still wouldn’t be as precise and accurate of an end result. Or you could use a “live trace” operation to have the computer guess where the lines should be based on the pixels in the image, but that’s even worse most of the time.

Instead if you look at a design like this and think – how can I get the shape I’m looking for by removing one shape from another shape – or by adding multiple shapes together – or by capturing only the area where two shapes intersect – you can get some really complex shapes with relatively little work.

The featherboard is a perfect use case. At the end of the day, it’s a board that has a 20 degree cut made at the top, with a bunch of thin, equally-spaced rectangles “added on” for fins that have that same 20 degree cut. The two side rails that we’ll use to slide the featherboard closer and further away from the table saw blade? Two rounded rectangles with a smaller rounded rectangle cut out of the center. Merge all those pieces together and boom, featherboard. Optionally add your logo for good measure if you’re a YouTuber since this jig may be full frame at times in future videos.

With the outlines created, it was time to head to the laser. I decided to pull out my 4 inch lens for my Thunder Laser, as it’s better at cutting through thicker stock than the 2 inch lens is. Though, since it’s pine and pine is relatively soft, the 2 inch lens could have probably handled it, as I found in my lens testing video, but the 4 inch lens is just better suited for this type of application so why not use it?

As for settings, I took it slow at 5 millimeters per second with the power at 85%. This was on my 80 Watt Thunder Nova 35; your settings will obviously vary depending on your machine. It may not look like it, but this shape has a large perimeter length because of all the fins/blades/teeth – whatever you want to call them. Because of how slow I was going, not counting the logo etch, it took about 12 minutes. But that’s still way faster than it would take me to make one in the manual fashion. Plus as long as you don’t abandon the machine entirely, it can be going while you are working on other things in the shop. Or you can stand and watch it like a kid in a candy store window, because lasers are fun to watch, even when you’ve been doing this for 6 years.

I was super happy with how it came out! The fins were super stiff, but had enough flexibility to work well as intended. Plus they make a fun sound when you run your finger down the length like you might an instrument.

Now I could have bought knobs and t-rail bolts for this project, but I figured I’d make it as DIY as I could and make the knobs from laser cut parts as well. Making a knob with any number of points in Illustrator is super easy. I’ve found the best way to make them is by using the Star tool. While dragging out a star, hold the “Command” key on Mac (probably Control key on Windows) and as you move your cursor, instead of the Star center getting bigger, the points themselves will get longer. Once you’re done drawing it, changing to the Direct Select Tool will show all the corner points on the star that can be made rounded. Pulling any one of them as far as it will go will force all the points to round over and meet at the half-way points between them. The reason we want a really pointy star to start out with is so that the “nubs” of the handle are more pronounced once we round them over.

I decided I would make my hold downs by using a flat head machine screw, a washer that fits perfectly within my table saw slot, and a few hex screws to hold the washer down. On the knob side of things, I decided to inset a hex bolt and sandwich it between the wood and a washer with some quick epoxy to hold it all together.

Once the epoxy cured, the hold downs were ready to use and as such, my featherboard was complete. To mount it to the table saw, it was simply a matter of putting one of my T-track washer contraptions in the bottom of each of the featherboard slots, followed by one of the knobs and twisting them on a majority of the way, only doing the final tightening once it had been slid into place.

And it worked like a charm! Nice and secure on the saw, and like I said the fins are nice and stiff with plenty of flexibility – but it actually needs to be used to be sure, right? I decided to put it to the test by cutting the factory-rounded edges off of a long length of 1 by 4 I had sitting around, and yup, it worked like a charm! Holding the board safely against the table saw fence, even though I standing well-behind the saw.

So this was a super quick video to put together and honestly I didn’t spend too long on it from start to finish, so while editing this video I’ve had some time to think about what I might want to improve about it. My only complaint is that the knobs sometimes turn a bit freely at the end of tightening and require me holding the stem of the screw in place for a second while I finish tightening them. I think this is because the 1 inch washers are a perfect fit in the T-slot and can freely rotate within the rails of the table saw. To fix this, I think what I’ll do is use some larger washers, perhaps 1 1/8 or so, and then square off two sides on the belt sander to make only one dimension fit the slot so it can’t freely rotate within.

Other than that, this works great and if it ever loses teeth or gets too beaten up, laser cutting a new one is just a quick 12 minute laser job away.

If you’d like to download my modified version of this featherboard in both vector PDF and Lightburn format, I’ll have a link down in the description where you can find that.

I’ll also link to Steve Ramsey’s video that inspired this project, where you can learn a bit more about featherboards and how they’re used. Steve is an excellent teacher for those starting woodworking.

That’s it for this one! If you’d like to see future laser cut shop jigs and projects like this one, be sure to subscribe so you don’t miss out. Until next time, cheers!

If you’d like to see more about how I made these, be sure to check out the build video at the top of the page. To grab the template, in both vector PDF and Lightburn format, fill out the form below and I’ll send it right over!

Get the template!

Want the template to make a laser cut featherboard for yourself? Drop me your email and I’ll send the PDF and Lightburn files right over, pronto!

Ready to make a featherboard yourself?

If you’re an Amazon user and want to support my channel, using the link below will give me a small kickback from Amazon at no extra cost to you as you find the machine bolts, washers, etc. that you want to use for your knobs. Thanks in advanced!